2025

From Foundation to Roof: 10 Surprising Applications of Butyl Rubber Sheet Waterproofing

When most people think of waterproofing in buildings, they imagine bituminous membranes, cementitious coatings, or liquid-applied membranes. Yet a modern hero is quietly gaining ground across the construction industry: butyl rubber sheet waterproofing. This high-performance elastomer brings flexibility, impermeability, and durability to a surprisingly wide range of applications. In this article, we’ll walk through ten surprising ways in which butyl rubber sheet waterproofing is used.

Why Butyl Rubber? The core advantages

Before looking at the applications, let’s get to know why butyl rubber is unique:

Low permeability:

Butyl rubber offers exceptional resistance to water, gases, and vapour, which makes it an ideal choice for watertight sealing.

- Chemical and environmental resistance:

It resists acids, alkalis, oils, UV, ozone, and ageing.

- Flexibility over a wide temperature range:

It remains supple in the cold, and it also does not degrade in extreme heat, making it ideal for climates with variations.

- Ease of adhesion or sealing:

Many butyl membranes are self-adhesive or bond easily to the base, ensuring tight continuity at joints.

- Durability:

Properly installed, butyl membranes can last many years with minimal maintenance.

These strengths make it far more than “just another waterproofing membrane”. Now, let’s traverse a building from bottom to top and see how butyl rubber sheets perform in each zone.

Foundation and Basement Waterproofing:

At the very root of the building, handling groundwater and soil moisture is essential. Butyl waterproofing rubber sheets serve as a wrap-around membrane on the exterior of basement walls or footings. Their low permeability ensures that even under hydrostatic pressure, water cannot permeate. Compared to more common membranes, butyl systems resist soil chemicals and biological elements far better.

Because of their chemical stability, butyl sheets act as a robust barrier, guarding against humidity, swelling soils, and occasional penetrations (like pipe stubs).

Tunnel, Retaining Wall, and Subterranean Structures

Going deeper underground, structures such as tunnels, parking garages, or retaining walls may experience severe moisture and chemical stress. Butyl rubber membranes find a niche there:

- They cope with negative-side waterproofing (i.e., water pressure pushing inwards).

- Their resistance to salt and chemical attacks from soil is beneficial.

- Their flexibility allows them to absorb small deformations or shifts in the structure.

Thus, butyl sheets are a trusted option for high-performance subterranean waterproofing.

Planter Boxes, Green Roofs & Roof-Garden Liners

Install a layer of soil and plants on your roof, and you need a liner that resists root intrusion, moisture migration, and pressure. Butyl rubber sheets step in elegantly:

- They provide a waterproof liner under the growing medium.

- They resist root penetration (with proper root-barrier lining).

- They remain flexible under load and temperature fluctuation.

- Hybrid membranes combining butyl with reinforcement (e.g., HDPE facing) are used in roof gardens.

Thus, even an elevated garden is protected from leakage into the structure below.

Podium, Terraces & Balconies

These horizontal, often trafficable bases demand membranes that can flex, survive foot traffic, and prevent ponding issues on them. Butyl rubber is better for:

- Self-adhesive or fully adhered sheet installations.

- Seam sealing to maintain continuity under mechanical movement.

- Handling UV exposure is covered or appropriately protected.

By combining a butyl sheet with a wear or screed topping, balconies can be made more resilient and leak-free.

Roof Membranes (Flat or Low-Slope Roofs)

It may surprise many, but the butyl waterproofing membranes are used as single-ply roofing, also called “Butynol roofing” (a butyl-based membrane form) — particularly in flat or low-slope applications.

Advantages here include:

- A seamless, continuous covering that resists ponding and water intrusion.

- Compatibility with insulation and roof build-ups.

- Durability under UV (if covered or modified).

- Good adherence to rooftop penetrations and detail work.

It’s a “foundation-to-roof” solution in the truest sense.

Pipe Penetrations, Flashings & Detail Waterproofing

Often the small loopholes in waterproofing are the small penetrations, like pipe stubs, drains, corners, and the parapet junctions. Butyl rubber excels in these details:

- Self-adhesive butyl tapes conform around irregular shapes.

- It works as flashing material against metals, masonry, and other surfaces.

- Because it remains flexible, joint movement (thermal expansion, settling) does not crack the seal.

By reinforcing these fail-prone zones, a butyl sheet system helps guarantee long-term watertightness on the roof.

Metal Roof Retrofit & Overlaying

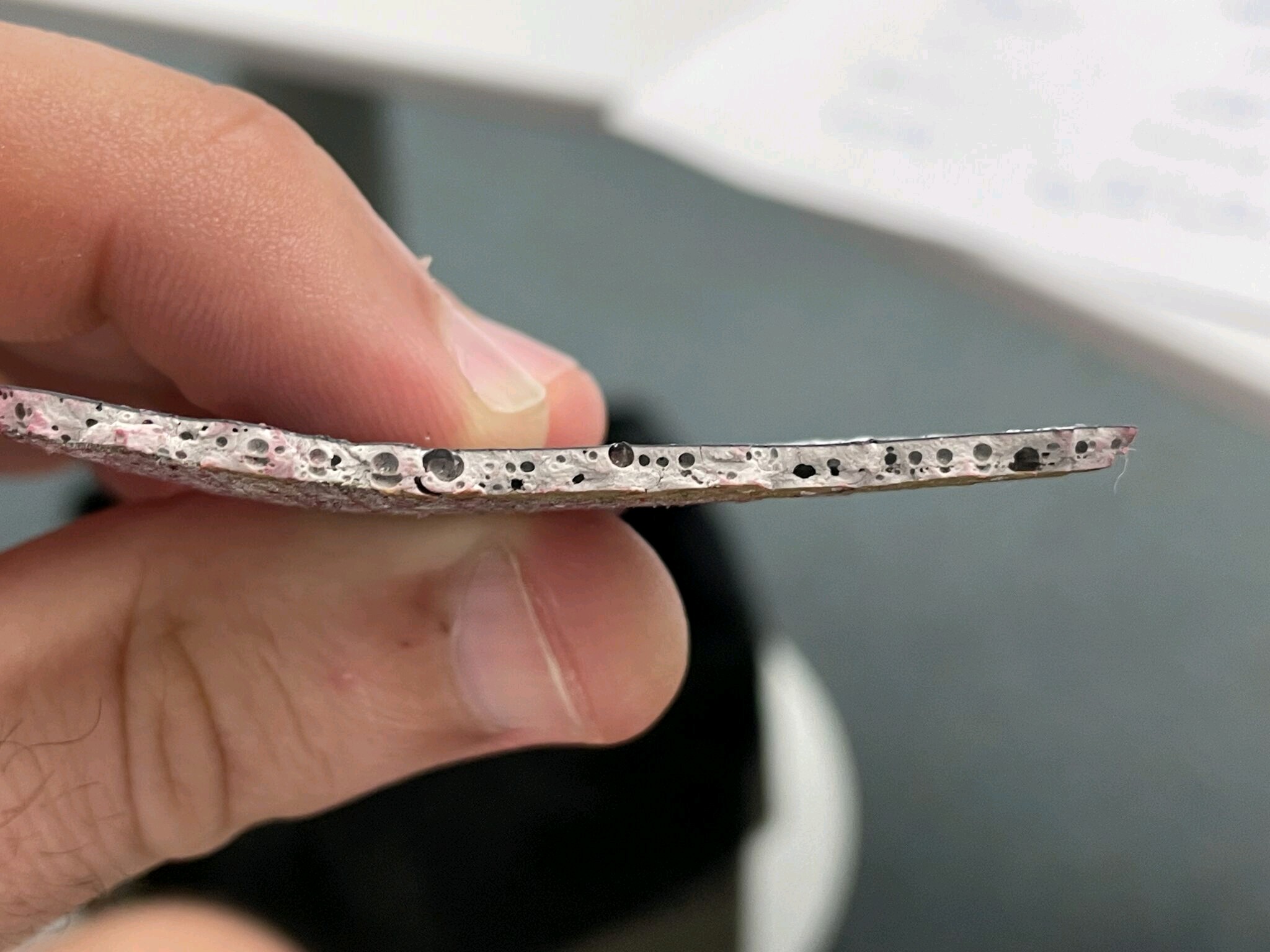

In many re-roofing cases, it’s impractical to strip the old metal roof. Instead, a butyl waterproofing rubber membrane can be applied over or between metal sheeting layers. Here it is:

- Acts as a continuous waterproof diaphragm under metal cladding.

- Bonds to metal substrates with appropriate adhesion (avoiding fastener penetration zones).

- Offers extra corrosion protection and leak resistance.

It’s a clever, lower‑cost way to upgrade older sheet-metal roofs.

Water Features, Ponds, & Reservoir Liners

You don’t often hear about “rubber sheets” in garden ponds or reservoirs — butyl membranes are used as liners for water retention:

- Their watertight nature ensures no leakage.

- Chemical stability makes sure that the aquatic life is safe.

- Large factory-seamed butyl liners can cover ponds, canals, and containment basins.

So, from landscaping to industrial reservoirs, butyl sheets are quietly doing heavy duty.

Roofing Underlays & Vapour Barriers

In some roof assemblies, a butyl waterproof rubber sheet can be used as a vapour barrier or an underlay beneath the primary roofing membrane. Because of its low vapour permeability, it helps control moisture movement from interior spaces upward. Additionally, in hybrid roofing systems, butyl membranes may act as a base layer that future roofs adhere to.

Sound & Vibration Damping, Insulation Backing

Beyond pure waterproofing, butyl rubber finds surprising use as a damping layer in building assemblies:

- It can reduce structural vibrations in the roof, acting as an elastic layer.

- It can be used beneath roofing panels or metal trays to reduce sound or impact noise.

- In multi-layer composite roof builds, it may serve as an intermediate “cushion” layer that protects the waterproofing above from structural stress.

Thus, the property that makes butyl great for sealing also makes it useful in quieting and stabilising building systems.

Butyl rubber vs Common alternatives

| Property / Criterion | Butyl Rubber Sheet | Typical Bitumen / SBS Membrane | EPDM / Other Synthetic Rubber Sheets |

| Water & vapor permeability | Very low (excellent barrier) | Moderate to low | Low, but often higher than butyl |

| Chemical/soil resistance | Excellent | Good, but can deteriorate under harsh soil | Good, but variable |

| Flexibility at low temps | Retains flexibility | May become brittle in cold | Good, but performance depends on formulation |

| UV / ozone aging | Good (if protected or modified) | Can degrade with cracking | Varies; EPDM tends to do well under UV |

| Ease of adhesion/sealing | Self-adhesive or bondable | Requires heat or adhesives | Some types require adhesive or welding |

| Seam/detail continuity | High (with tape and overlap systems) | Moderate; heat welding needed | Good, but jointing methods vary |

| Service life / durability | Very good | Good if protected | Good, especially under adequate protection |

| Multi‑function use (damping, etc.) | Strong potential | Less suited | Varies |

Frequently Asked Questions

1. How long does the butyl waterproofing rubber sheet last?

The rubber membrane lasts 15-25 years and protects against water leaks, UV exposure, and many other factors, provided it is properly installed and maintained. In some cases, it can last for over 25 years as well.

2. Can Butyl sheets be used under tiles?

Yes, the waterproof sheets can be laid under the tiles and screeds, but make sure the areas are not punctured due to pressure.

3. Is a Butyl sheet suitable for roofs in hot climates?

Absolutely! These sheets not only protect the structure from leaks but also protect it from UV radiation.

4. Can a Butyl waterproof rubber sheet handle water ponding?

Yes. Because of their water resistance and flexibility, many butyl systems are designed to withstand standing water without immediate failure. Proper slope and drainage are still recommended along with this.